基于机器视觉的软包装锂离子电池的表面凸点缺陷检测

来源:《电池》

Surface bump defect detection for pouch Li-ion battery

ZENG Zhen1,2,WANG Hong-bo1,2∗,WANG Zheng-jia1,2,HE Tao1,2

( 1.Hubei key Laboratory of Modern Manufacturing Quality Engineering,Wuhan,Hubei 430068,China;2.Hubei University of Technology,School of Mechanical Engineering,Wuhan,Hubei 430068,China )

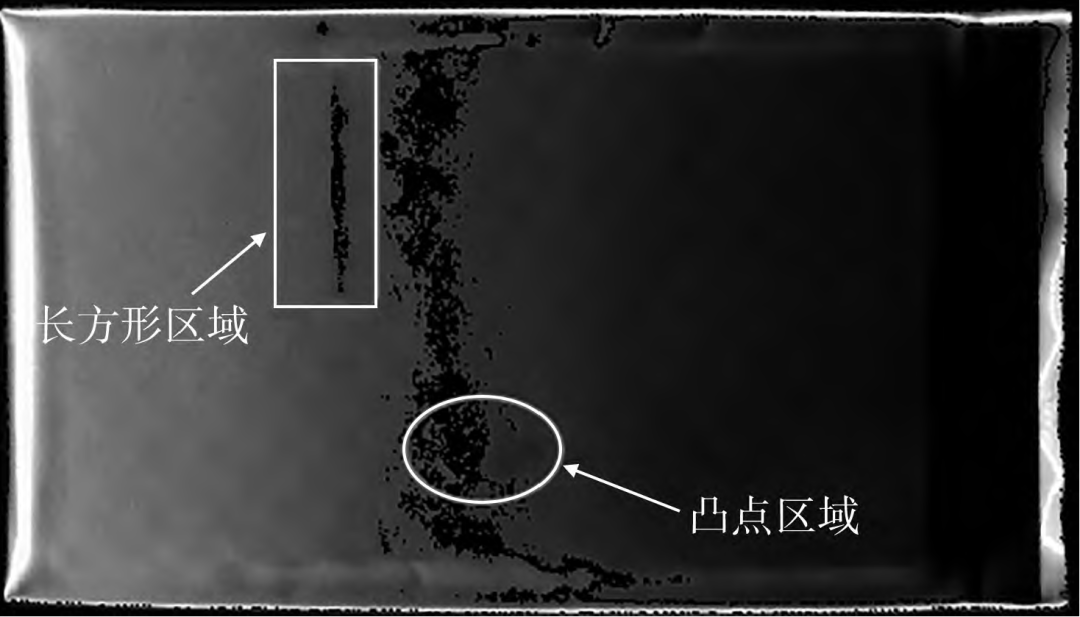

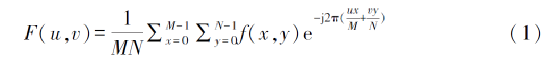

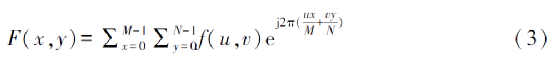

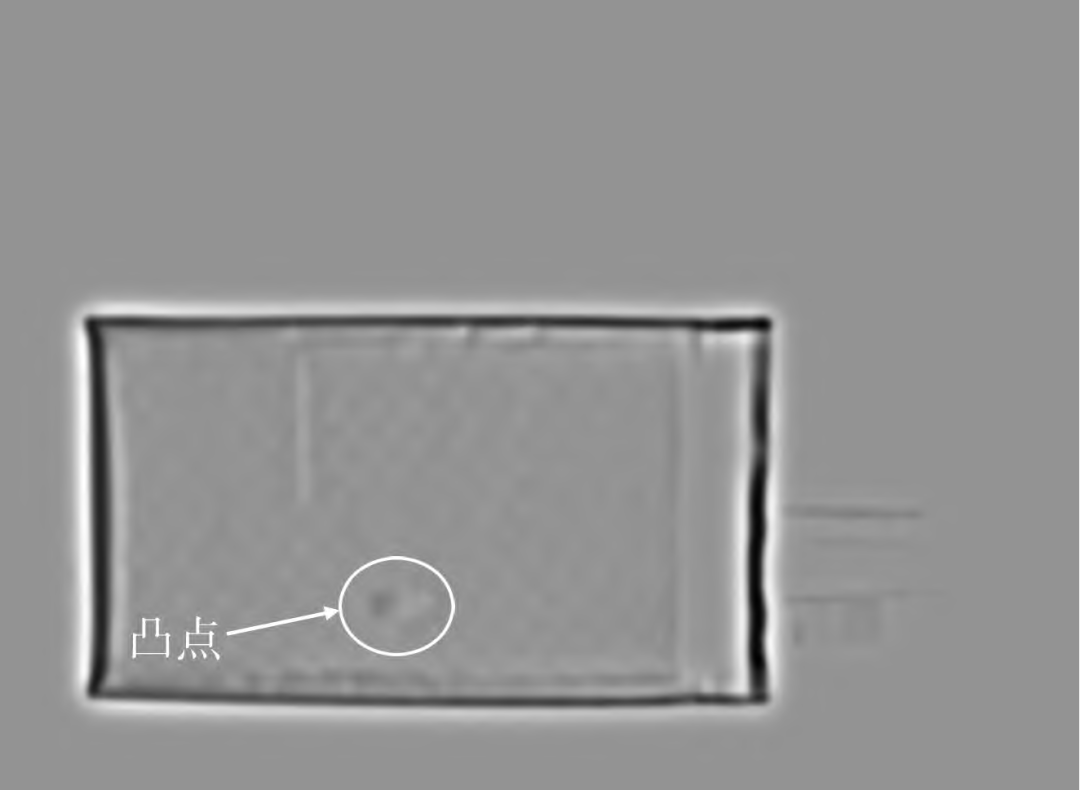

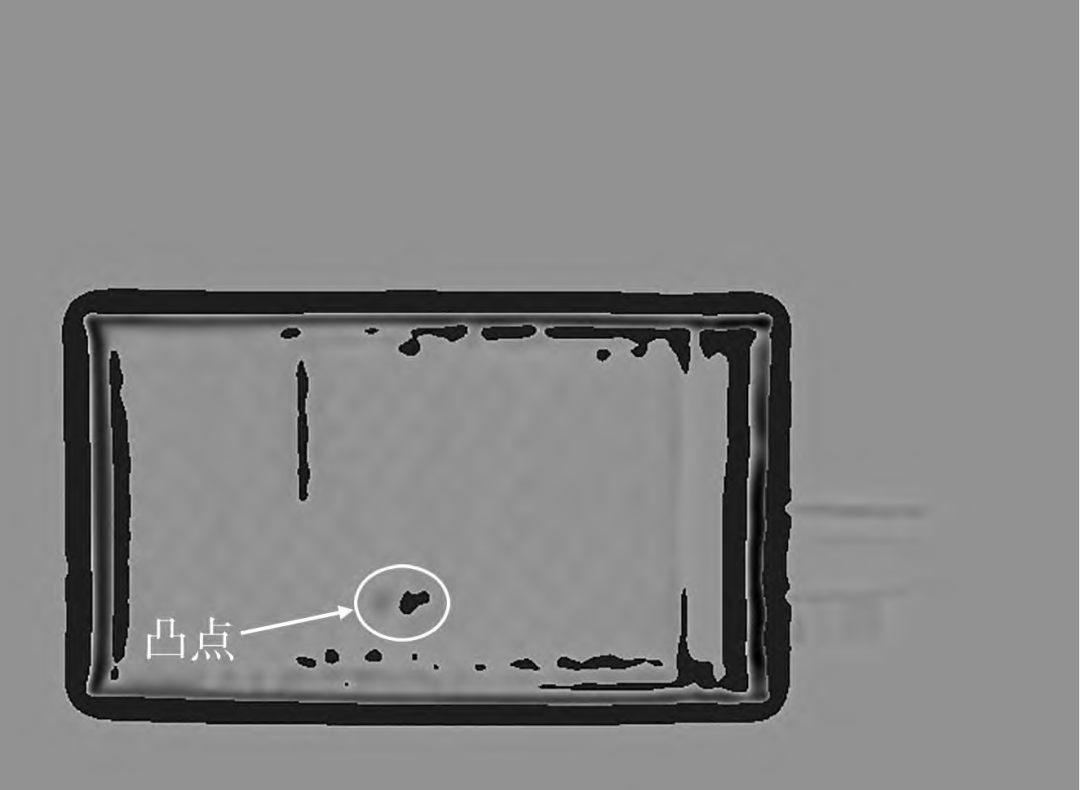

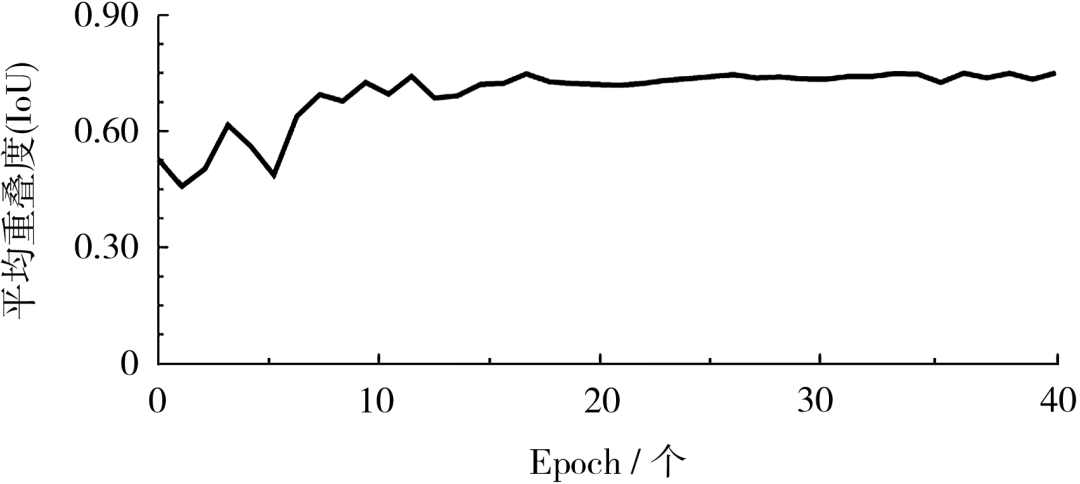

Abstract:Because of the uneven and reflective appearance of the aluminum-plastic film outer packaging of the pouch Li-ion battery,the identification of the bump defect of the surface image was low,which was difficult to be accurately identified by traditional methods. The image features of bump defects of pouch Li-ion battery and visual detection system were analyzed. Gaussian filter was used to preprocess the image in frequency domain to achieve the effect of removing noise and image enhancement of defect area. Inverse Fourier transform was used to transfer the image from frequency domain to space domain. Finally,the processed image was imported into the deep learning model based on semantic segmentation method for bump defect detection. 400 groups of defect samples were tested,the results showed that the defect detection accuracy of pouch Li-ion battery by proposed method reached 95.75%. The detection accuracy without processing with frequency domain image enhancement method was only 44. 00% . The

detection results had been significantly improved,which proved that the method could detect the low recognition bump defects of the surface image of the pouch Li-ion battery and had a certain practical value.

Keywords:frequency domain; image enhancement; pouch Li-ion battery; bump; defect detection

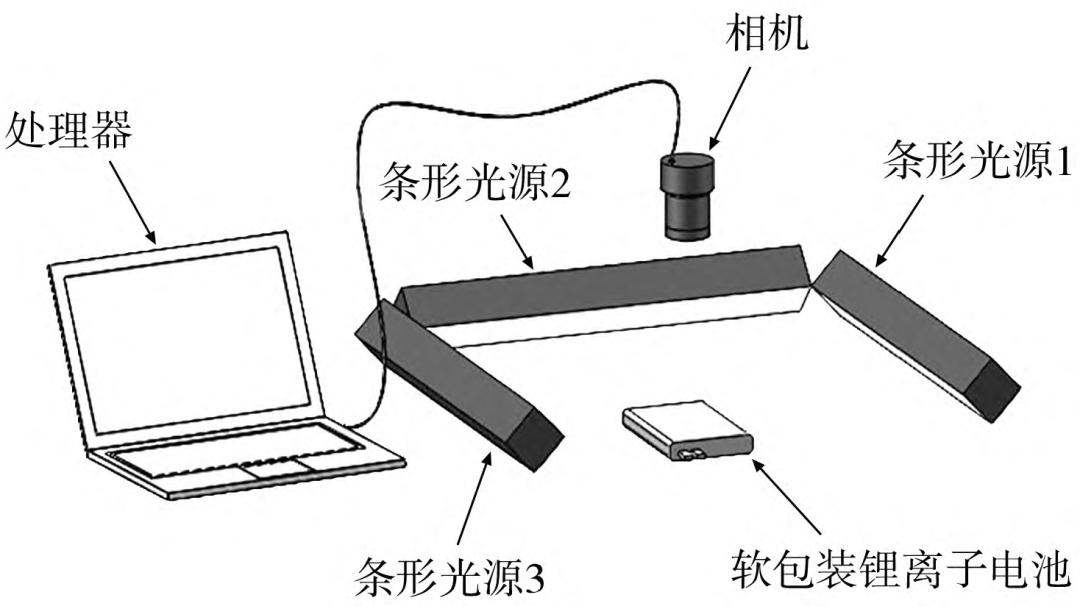

1 软包装锂离子电池表面缺陷检测系统

3 验证结果

缺陷类别 |

数量/只 |

误检率/ % |

准确率/ % |

|||

样本数 |

正确检测 |

漏检 |

误检 |

|||

合格 |

200 |

110 |

0 |

90 |

45.00 |

55.00 |

凸点 |

200 |

66 |

0 |

134 |

67.00 |

33.00 |

总计 |

400 |

176 |

0 |

224 |

56.00 |

44.00 |

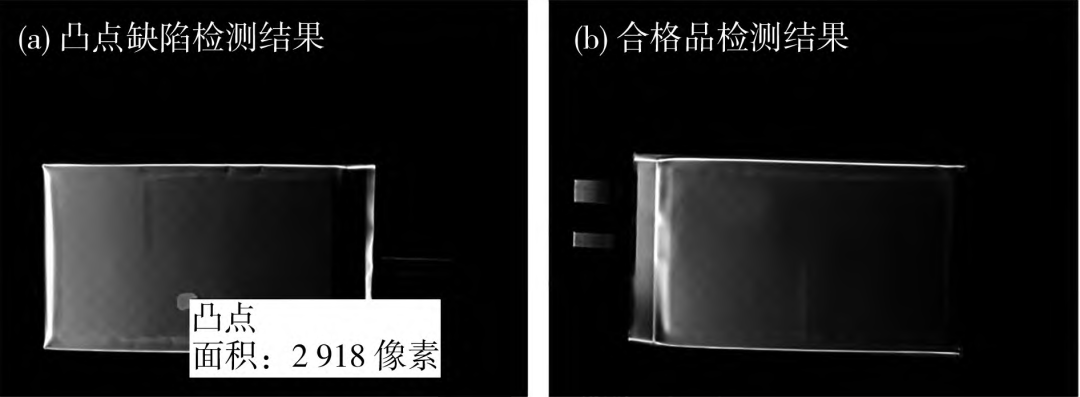

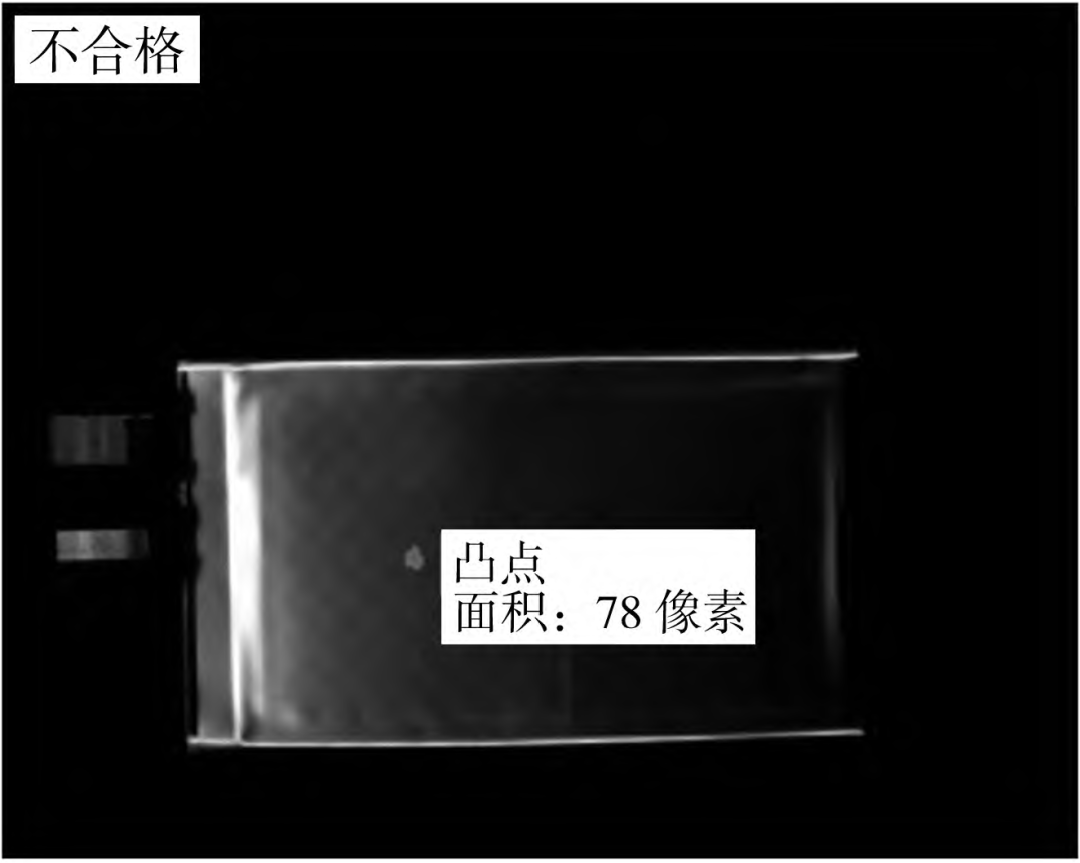

缺陷类别 |

数量/只 |

误检率/ % |

准确率/ % |

|||

样本数 |

正确检测 |

漏检 |

误检 |

|||

合格 |

200 |

191 |

0 |

9 |

4.50 |

95.50 |

凸点 |

200 |

192 |

0 |

8 |

4.00 |

96.00 |

总计 |

400 |

383 |

0 |

17 |

4.25 |

95.75 |

序号 |

凸点外接圆直径/mm |

绝对误差/mm |

相对误差/% |

|

测量值 |

真实值 |

|||

1 |

1.47 |

1.41 |

0.06 |

4.08 |

2 |

5.23 |

5.37 |

0.15 |

2.87 |

3 |

7.82 |

7.68 |

0.14 |

1.79 |

4 |

3.17 |

3.09 |

0.08 |

2.52 |

5 |

8.62 |

8.84 |

0.22 |

2.55 |

6 |

2.14 |

2.07 |

0.07 |

3.27 |

7 |

4.73 |

4.59 |

0.14 |

2.96 |

8 |

7.51 |

7.28 |

0.23 |

3.06 |

9 |

1.98 |

1.92 |

0.06 |

3.03 |

10 |

4.43 |

4.57 |

0.14 |

3.16 |

4 结论

参考文献:

[1] 胡丽娜,孙珊珊,岳娟,等.锂离子电池气胀原因探讨[J].电池,2021,51(3):261-265.

HU L N,SUN S S,YUE J,et al. Discussion on the causes of Li-ion battery swelling[J]. Battery Bimonthly,2021,51(3):261-265.

[2] CHEN Y G,SHU Y F,LI X M,et al. Research on detection algorithm of lithium battery surface defects based on embedded machine vision[J].J Intell Fuzzy Syst,2021,41(3):4327-4335.

[3] 刘春,利新琴,鲁昌华,等.密封橡胶圈凸点缺陷检测的研究[J].电子测量与仪器学报,2008,22(S2):178-181.

LIU C,LI X Q,LU C H,et al. Research on detection method for convex dot defect of rubber ring[J].Journal of Electronic Measurement and Instrument,2008,22(S2):178-181.

[4] 黄梦涛,连一鑫.基于改进Canny算子的锂电池极片表面缺陷检测[J].仪器仪表学报,2021,42(10):199-209.

HUANG M T,LIAN Y X. Lithium battery electrode plate surface defect detection based on improved Canny operator[J].Chinese Journal of Scientific Instrument,2021,42(10):199-209.

[5] 肖艳军,齐浩,周围,等. 锂电池极片轧机轧辊表面缺陷检测与识别[J].电子测量与仪器学报,2019,33(10):148-156.

XIAO Y J,QI H,ZHOU W,et al. Detection and recognition of roll surface defects in lithium battery strip mill[J].Journal of Electronic Measurement and Instrument,2019,33(10):148-156.

[6] GB/ T 33143—2022,锂离子电池用铝及铝合金箔[S].GB/T 33143—2022, Aluminium and Aluminium Alloy Foils for Lithium Ion Batteries[S].

[7] 张鹏博,张晓华,王训,等.锂离子电池用铝塑复合膜精密冲压工艺研究[J]. 热加工工艺,2016,45(7):167-170.

ZHANG P B,ZHANG X H,WANG X,et al. Study on precision stamping process of Al-plastic compound film for Li-ion battery[J]. Hot Working Technology,2016,45(7):167-170.

[8] 章毓晋. 图像工程(上册):图像处理和分析[M]. 北京:清华大学出版社,1999:72.

ZHANG Y J.Image Engineering(Volume 1):Image Processing and Analysis[M]. Beijing:Tsinghua University Press,1999:72.

[9] 孙振兴. 基于DSP 的图像增强技术研究[D]. 西安:西安电子科技大学,2012.

SUN Z X. Research on image enhancement technology based on DSP[D]. Xi’an:Xidian University,2012.

[10] 李庚银,陈志业,宁宇.快速傅里叶变换的两种改进算法[J].电力系统自动化,1997(12):37-40.

LI G Y,CHEN Z Y,NING Y. Two improved algorithms of fast Fourier transform [J]. Automation of Electric Power Systems, 1997(12):37-40.

[11] 李健,丁小奇,陈光,等. 基于改进高斯滤波算法的叶片图像去噪方法[J]. 南方农业学报,2019,50(6):1385-1391.

LI J,DING X Q,CHEN G,et al. Blade image denoising method based on improved Gauss filtering algorithm[J]. Journal of Southern Agriculture,2019,50(6):1385-1391.

[12] 司祯祯. 傅里叶变换与小波变换在信号去噪中的应用[J].电子设计工程,2011,19(4):155-157.

SI Z Z. Application of Fourier transform and wavelet transform in signal de-noising[J]. Electronic Design Engineering,2011,19(4):155-157.

[13] WULFF F, SCHÄUFELE B, SAWADE O, et al. Early fusion of camera and lidar for robust road detection based on U-Net FCN[C]//2018 IEEE Intelligent Vehicles Symposium (IV).IEEE,2018:1426-1431.

[14] CSURKA G, PERRONNIN F. An efficient approach to semantic segmentation[J]. Int J Comput Vision,2011,95(2):198-212.

声明:部分内容来源于网络,仅供读者学习、交流之目的文章版权归原作者所有。如有不妥,请联系删除。